|

Corrosion-Resistant Hopper

Corrosion-Resistant Hopper

SPEED-CASTER™ 525 and SPEED-CASTER™ 900 tailgate spreaders feature corrosion-free poly hoppers for long-lasting durability. |

|

Material Delivery

Material Delivery

Material is delivered by a heavy-duty steel auger to provide long-lasting, reliable performance.

If an obstruction occurs, the transverse auger system will reduce downtime by automatically reversing until the obstruction is cleared and then normal operation will resume. |

|

Mounting Options

Mounting Options

The SPEED-CASTER™ 525 tailgate spreader comes standard with a combination 2″ receiver hitch and 3-point tractor mount for use on multiple vehicle types.

The SPEED-CASTER™ 900 tailgate spreader* requires the additional purchase of one of the available mount options: a pivot mount, a 2″ receiver hitch mount (requires additional adapter), or a 3-point hitch mount.

*Mounts sold separately. |

|

|

|

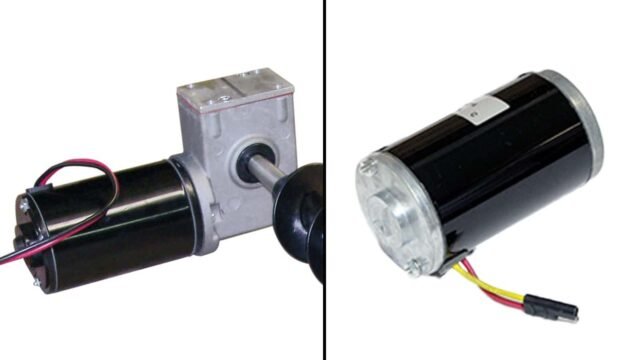

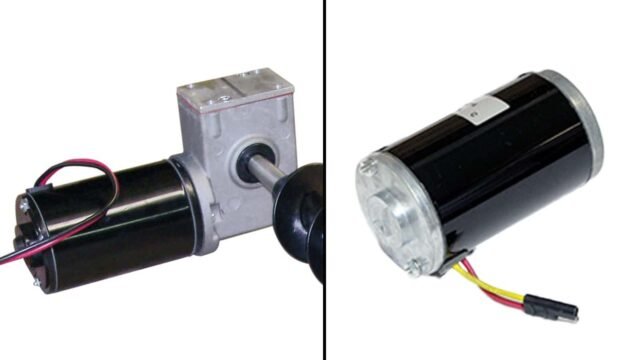

Dual Electric Motors

Dual Electric Motors

The two high-torque 12-volt electric motors provide quiet, reliable, independent control over the auger and spinner mechanisms. The spinner motor is sealed inside a weather-resistant housing, protecting it from corrosion. |

|

Controls

Controls

Enhanced, dual variable-speed control allows you to precisely match material delivery and spread patterns to conditions. Three standard accessory buttons and a dedicated blast button provide optimum in-cab efficiency.

Easy-to-understand, digital self-diagnostics alert the operator when the spreader is empty or when adjustments are needed, and LEDs make the control easy to read. Its compact size compared to traditional controls fits easily into today’s modern truck cab designs. |

|

Spinner

Spinner

The SPEED-CASTER™ 525 tailgate spreader features a 10″ spinner made of nylon/glass reinforced resin, and delivers a spread pattern of up to 30′.

The SPEED-CASTER™ 900 tailgate spreader features a 12″ steel spinner (shown above) and delivers a spread pattern of up to 40′. |

|

Accessory Integration

Accessory Integration

Conveniently connect accessories directly into the spreader module mounted in the spinner motor enclosure. Accessories automatically integrate with the tailgate control without having to run additional wires from the front of the truck. |

|

Inverted V / Vibrator

Inverted V / Vibrator

An inverted V comes standard and helps keep sufficient material weight off of the auger, ensuring smooth startup and flow of material. It is directly connected to the vibrator to help reduce bridging and keep material moving to the auger. |

|

Top Screen

Top Screen

A steel top screen comes standard, which helps break up large chunks of de-icing material during the loading process to prevent clogging and bridging during spreader operation. |