HELIXX™ AUGER TECHNOLOGY HELIXX™ AUGER TECHNOLOGY

Patent-pending corkscrew material delivery system is optimized to operate in the target range for rock salt spreading best practices. The auger has multiple pitches to help promote smooth, even material flow from the hopper and prevents bridging. The shaftless technology reduces drag on the motor and reduces the overall load on the electrical system.

* Auger Models Only (S035A & S070A)

|

|

PINTLE CHAIN CONVEYOR

The large conveyor delivers reliable, smooth, and consistent material flow for heavy, dense materials while reducing bridging.

* Chain Models Only (S035C & S070C)

|

|

HOPPER CONSTRUCTION HOPPER CONSTRUCTION

The hopper is made from corrosion-resistant stainless steel and constructed entirely of rivets and bolts, with no welding. This provides a cleaner stainless look and is easier to repair for long-life and protection against stress.

|

|

EXTENDED MATERIAL DELIVERY & PRE-WET CHAMBER

A material delivery extension reduces leaking/spilling during transport. This provides a more cab forward design, allowing for added stability and weight distribution of the hopper.

When equipped with the optional pre-wet accessory (S070C/S070A Models Only), it leads into the patented pre-wet mixing chamber.

|

|

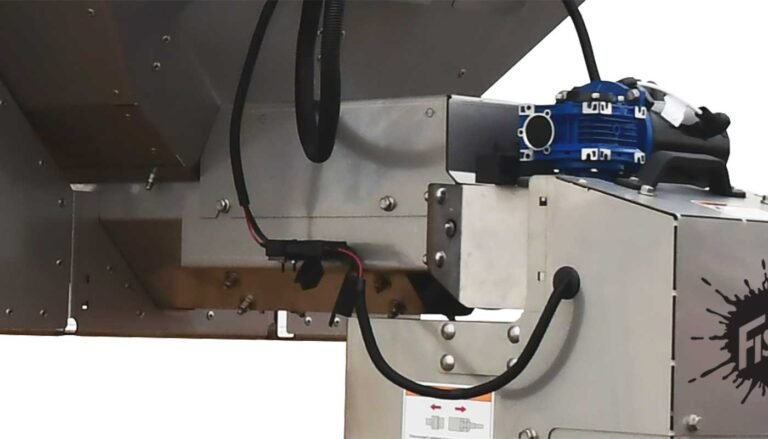

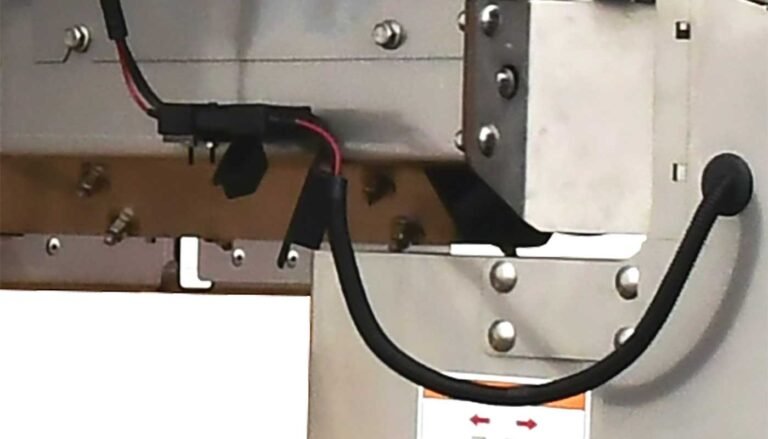

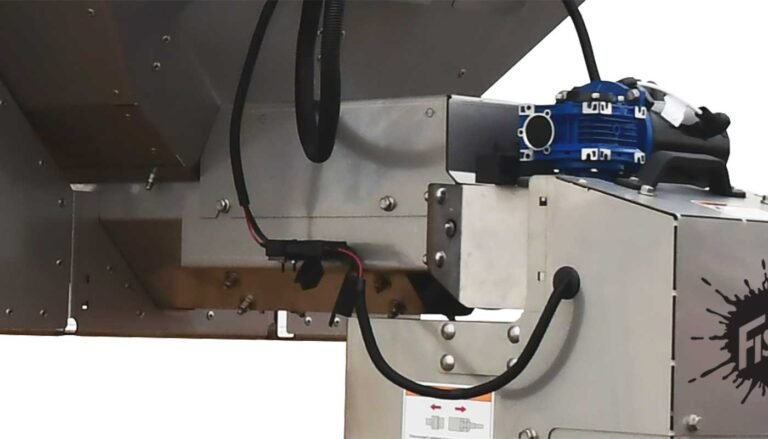

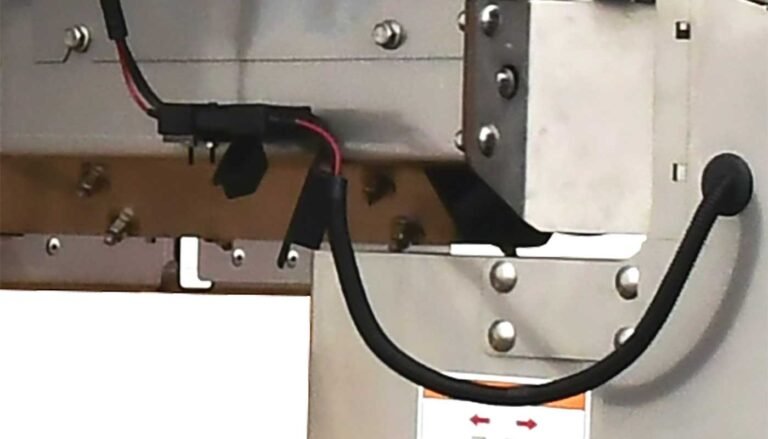

WIRING CHANNEL FOR EASE OF INSTALL WIRING CHANNEL FOR EASE OF INSTALL

Channels on either side of the hopper allow wires and cables to be easily run from the hopper to the cab for a clean installation.

|

|

CHUTE DESIGN CHUTE DESIGN

Baffles within the chute deliver a consistent spread pattern that reduces material waste. By directing material to precise points on the spinner, it helps to cast it away from the truck rather than onto the back of your bumper. A direct drive motor offers better torque and reduces servicing.

|

|

CHUTE ASSEMBLY CHUTE ASSEMBLY

For precise material application, the chute assembly can be configured for either pickup truck or flatbed and dump body applications, ensuring you’re always spreading at the optimum height. An extended chute is standard on 0.35 and 0.7 models.

The ergonomic, hinged design allows the chute to flip up, providing easy access for maintenance or material unloading. For convenient access to the hitch, the chute assembly can be removed.

|

CHUTE POWER PLUG CHUTE POWER PLUG

Heavy-duty, weather resistant plug is IP-68 rated. Positive latching ensures a secure connection, even with vibrations caused by consistent travel. The plug has been tested to 5,000 mating cycles for durability for many winter seasons to come. |

SPINNER CHANNELS & SPREAD PATTERN SPINNER CHANNELS & SPREAD PATTERN

A 12″ polyurethane spinner delivers a broadcast spread pattern of up to 30 feet and provides long-lasting, corrosion-free performance. The ridges on the spinner ensure an even distribution of material throughout the spread arc. |

|

MATERIAL SPILL PROTECTOR (CHAIN ONLY) MATERIAL SPILL PROTECTOR (CHAIN ONLY)

A protection flap at the end of the conveyor prevents material from spilling out and pooling near the vehicle cab.

*Chain Models Only (S035C & S070C)

|

TOP SCREEN TOP SCREEN

A steel top screen comes standard, which helps break up large chunks of de-icing material during the loading process to prevent clogging and bridging during spreader operation. |

CHUTE POWER PLUG

CHUTE POWER PLUG SPINNER CHANNELS & SPREAD PATTERN

SPINNER CHANNELS & SPREAD PATTERN MATERIAL SPILL PROTECTOR (CHAIN ONLY)

MATERIAL SPILL PROTECTOR (CHAIN ONLY) TOP SCREEN

TOP SCREEN CONTROL

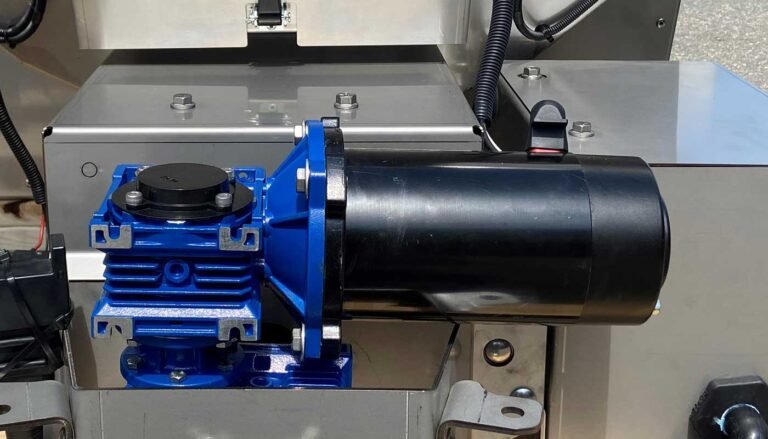

CONTROL ELECTRIC MOTOR

ELECTRIC MOTOR SHUTTER DEFLECTOR

SHUTTER DEFLECTOR ACCESSORY INTEGRATION & KNOCK OUTS

ACCESSORY INTEGRATION & KNOCK OUTS DUMP & WORK LIGHT SWITCHES

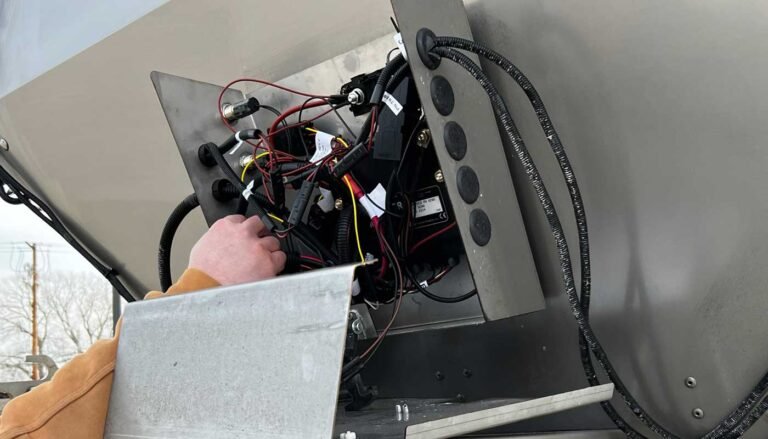

DUMP & WORK LIGHT SWITCHES FLEET FLEX ELECTRICAL SYSTEM

FLEET FLEX ELECTRICAL SYSTEM