POWERFUL CUT-OFF MACHINE WITH 14" CUTTING WHEEL

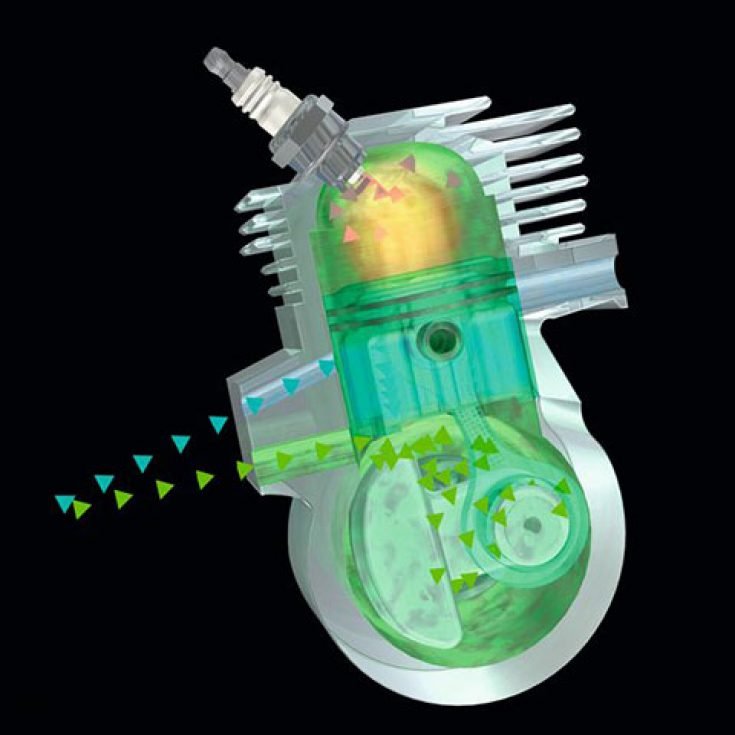

Thanks to its compact dimensions, road construction and landscaping professionals can use the STIHL TS 420 gas-driven cut-off machine to carry out particularly tough cutting tasks very reliably. Its powerful 350 mm cutting wheelallows for cutting depths of up to 125 mm in concrete, stone, asphalt, mild steel or through iron pipes. The STIHL anti-vibration system in the STIHL TS 420 ensures that you can guide the motorised cut-off machine precisely even during longer periods of use, protecting your muscles and joints. The ergonomic handle design also helps with this. To ensure you can start the economical STIHL 2-MIX engine with ease, the power tool also features a decompression valve that reduces the effort required to pull the starter cord.

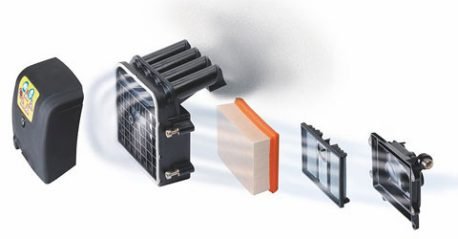

The water connection continuously supplies water to the cutting wheel of the STIHL TS 420 motorised cut-off machine. Water binds the dust and cools the cutting wheel, while the long-life air filter system and the compensator extend the cleaning interval and ensure you can work for longer periods without interruption. The separation of clean air and mixture in the engine boosts the performance while also reducing consumption. This video shows the TS 420 gas cut-off machine in action in construction and civil engineering settings.

|

STIHL ANTI-VIBRATION SYSTEM

STIHL ANTI-VIBRATION SYSTEM STIHL 2-MIX ENGINE

STIHL 2-MIX ENGINE LONG-LIFE AIR FILTER SYSTEM FOR CUT-OFF MACHINES

LONG-LIFE AIR FILTER SYSTEM FOR CUT-OFF MACHINES Semi automatic V-belt tensioning

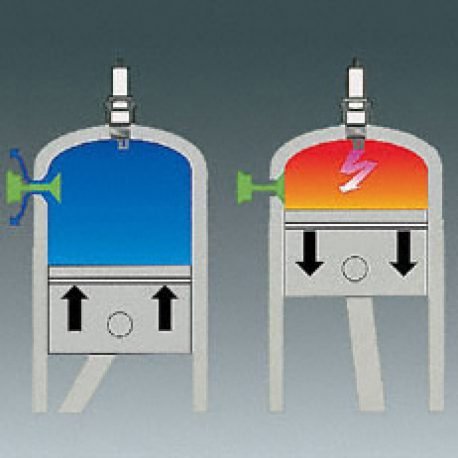

Semi automatic V-belt tensioning COMPENSATOR

COMPENSATOR MANUAL DECOMPRESSION

MANUAL DECOMPRESSION